Hobbs Meter Correction

-

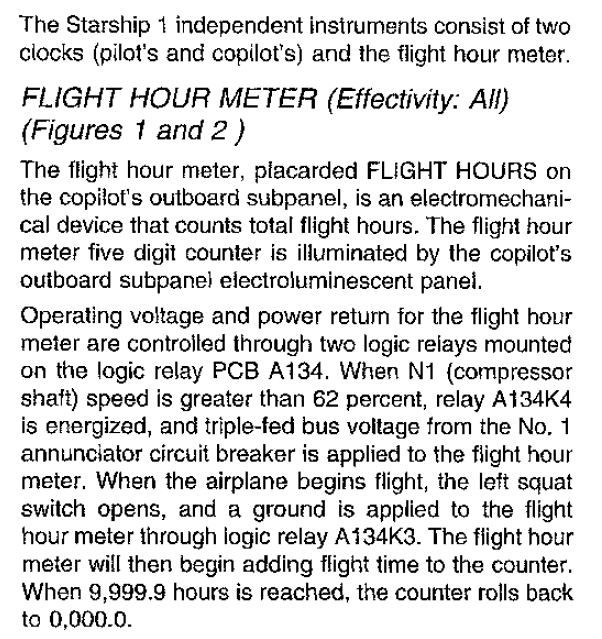

@Black-Square The hobbs meter in the starship seems to count as soon as the engine is started, but the AMM chapter 31 identifies the following logic is required for the flight hour meter to count up:

N1 > 62% & Left squat switch open. The first prevents the aircraft from counting if the aircraft is powered and on jacks, the second in the event of a ground engine run. I noticed this because I track flight time based on the CDU and the numbers after 20 plus hours of flying the aircraft is indicating 3-4 extra hours of flight time.

-

I played with a few ways of implementing this, but the two MSFS variables for recording engine time and flight time seem to be inconsistent in their behavior depending on how the flight was initiated. I haven't explored much further, as I don't consider the hobbs meter to be a headlining feature of my aircraft, if you catch my drift.

-

I played with a few ways of implementing this, but the two MSFS variables for recording engine time and flight time seem to be inconsistent in their behavior depending on how the flight was initiated. I haven't explored much further, as I don't consider the hobbs meter to be a headlining feature of my aircraft, if you catch my drift.

@Black-Square This does, however, confirm something I brought up in an earlier post. The Hobbs in the BKSQ Starship has five digits that only count whole hours, whereas there should be a visible decimal point, and the last counter should be counting tenths.

-

I played with a few ways of implementing this, but the two MSFS variables for recording engine time and flight time seem to be inconsistent in their behavior depending on how the flight was initiated. I haven't explored much further, as I don't consider the hobbs meter to be a headlining feature of my aircraft, if you catch my drift.

@Black-Square said in Hobbs Meter Correction:

I played with a few ways of implementing this, but the two MSFS variables for recording engine time and flight time seem to be inconsistent in their behavior depending on how the flight was initiated. I haven't explored much further, as I don't consider the hobbs meter to be a headlining feature of my aircraft, if you catch my drift.

@Black-Square would the simvars: CONTACT POINT IS ON GROUND:1 & ENG N1 RPM:2 > 62 & [triple fed bus v > 22 ] work?

I worked back from 77-12 to 21-51 to 31-21 to get all the logic and the textual description from above is as simple as that. If the right engine is above 62% N1 then K4 closes and power from the CWS triple fed bus goes into 24-54-03 CB104 (5Amp) then into Terminal Block 121 (31-51-07) and comes out pin F into the right side of the flight hour meter.

The K3 relay poles are either connected to the L. Stall Warn Comp through wire D102A22 on both upper and lower pole or ground through J280 ground block.

When the aircraft is on the ground and K3 is closed, then power from the L. Stall Warn computer wire D102A22 (21-31-01) is applied to both poles of K3. The upper pole connects straight to ground and the lower pole connects D102A22 to the left side of the flight hour meter. Power is being applied to both sides the hr meter and thus doesnt increment. when the left squat switch opens, K3 loses power and opens. The upper pole connects to Pin3 of P341 on 91-39 which is blank. The lower pole connects to ground and applies a ground to the left side of the hour meter, the difference in voltage causes the hr meter to increment. -

@Black-Square said in Hobbs Meter Correction:

I played with a few ways of implementing this, but the two MSFS variables for recording engine time and flight time seem to be inconsistent in their behavior depending on how the flight was initiated. I haven't explored much further, as I don't consider the hobbs meter to be a headlining feature of my aircraft, if you catch my drift.

@Black-Square would the simvars: CONTACT POINT IS ON GROUND:1 & ENG N1 RPM:2 > 62 & [triple fed bus v > 22 ] work?

I worked back from 77-12 to 21-51 to 31-21 to get all the logic and the textual description from above is as simple as that. If the right engine is above 62% N1 then K4 closes and power from the CWS triple fed bus goes into 24-54-03 CB104 (5Amp) then into Terminal Block 121 (31-51-07) and comes out pin F into the right side of the flight hour meter.

The K3 relay poles are either connected to the L. Stall Warn Comp through wire D102A22 on both upper and lower pole or ground through J280 ground block.

When the aircraft is on the ground and K3 is closed, then power from the L. Stall Warn computer wire D102A22 (21-31-01) is applied to both poles of K3. The upper pole connects straight to ground and the lower pole connects D102A22 to the left side of the flight hour meter. Power is being applied to both sides the hr meter and thus doesnt increment. when the left squat switch opens, K3 loses power and opens. The upper pole connects to Pin3 of P341 on 91-39 which is blank. The lower pole connects to ground and applies a ground to the left side of the hour meter, the difference in voltage causes the hr meter to increment.@ProfCrash said in Hobbs Meter Correction:

would the simvars: CONTACT POINT IS ON GROUND:1 & ENG N1 RPM:2 > 62 & [triple fed bus v > 22 ] work?

Yes, except I don't maintain the hobbs meter value. It's saved with the aircraft's core state in a file by Asobo, and it's incremented only by their simple rules in the configuration files. I could maintain my own variable, of course, but we have already seen how inconsistent state saving is in MSFS, and it would be one more inconsistent behavior for people to complain about. I know that persistent hobbs hours are a point of pride for many pilots, so I wouldn't want to risk losing their hours on them.